Download Solidworks Convert Revolve To Sheet Metalbackstage

- Convert Models To Sheet Metal Solidworks

- Solidworks Sheet Metal Tutorial

- How To Use Sheet Metal In Solidworks

Read this article to know the difference between solidworks and Autocad.

Here are the commonly asked solidworks interview questions and answers:

Create two revolved bosses to round out the louver. Add a fillet around the bottom edge of the louver. Use an extruded cut to remove the base so that only the louver remains. Use the Forming Tool tool to convert the louver into a forming tool. Today, we are going to show you the simple steps you can take to easily create a sphere in Solidworks. Creating a Sphere in Solidworks Let’s take a close look at these three simple commands and see how they can help us on the quest of creating our sphere in Solidworks.

Hi guys, I need to get a fat pattern out of a cone with knuckle attached, please refer to the model. When I flat the sheet metal, I have got 364.61mm for chord cutout and 14.43° for chord radius insdead of correct ones 311mm and 12.3° calculated by 'plate n sheet'. So let’s see what this information would look like in SOLIDWORKS. As you can see there are some parametric solids and some cross-sections which are all in their relative location to each entity. From here, we need to use our simple modeling tools such as: extrudes, revolves, lofts, etc. To create a revolve feature, use the following guidelines: The sketch for a solid revolved feature can contain multiple intersecting profiles. With the Selected Contours pointer (available when you click Selected Contours in the PropertyManager), you can select one or more intersecting or non-intersecting sketches to create the revolve.

Solidworks is a computer aided design tool used for the design, manufacturing and simulation of mechanical products. This tool can be used in the complete product development cycle. Here are the applications of solidworks:

- Concept design

- Detailed Part and Assembly Design

- Structural and thermal analysis

- Motion studies

- Tolerance Analysis

- Engineering Drawings

- Manufacturing

- Inspection e.t.c.

Solidworks Templates store a set of rules or default settings in various solidworks modules.

Solidwork Configurations allow users to create multiple variations of a part and assemblies within one document. They provide a convenient way to develop and manage families of cad models with different dimensions, components, or other parameters.

For example a family of screws or nuts can be defined by configurations in solidworks.

Here are the steps to create a new template in solidworks:

Step-1: Open the required SW module such as part, drawing or assembly.

Step-2: Modify required setting in solid works.

Step-3:

Convert entities are used in solid works to draw sketches with reference to any feature of a part.

Step-1:

Relations are used in solidworks sketch modules to define design intent. When we define a sketch, soliidworks automatically add relations. These relations can be edited manually as well.

Examples of Solidworks Sketch Relations include:

- Coincident, Midpoint, Merge and Pierce.

- Horizontal, Perpendicular Vertical and symmetric.

- Equal, Equal Slot.

- Co-linear, Parallel.

- Co-Radial, Concentric, Tangent and equal curvature.

- On edge, on plane, etc

Equations are used in solid works assembly and part modules to define the relationship in between two dimensions. Solidwork Equations use global variables and mathematical functions.

Following methods are used to constrain a spline in solidworks:

- Tangent/vertical/horizontal relations to spline direction.

- Dimensions on spline control.

- Constrain the position of spline points.

Here are the different types of patterns used in solidworks:

- Linear Pattern

- Circular pattern

- Curve driven pattern

- Sketch driven pattern

- Table driven pattern

- Fill pattern

- Variable pattern

Step-1: Go to insert and select reference geometry.

Step-2: Select Add Plane.

Step-3: Select reference for plane.

Shell is used to make uniform or variable thickness of a solid body.

Step-1: Open Sketch Module

Step-2: Go to Tools, Sketch Tools and then Sketch picture

Step-3: Browse the picture

Step-4: Open picture

Draft feature is used to provide an angle to a wall from a parting plane. Draft angle is generally used to facilitate easy removal of injection molded parts from injection tool.

Hole wizard is a tool inside solidworks that allows to quickly create standard & customized holes within a part or assembly without using multiple features.

- Linear component pattern

- Circular component pattern

- Pattern driven component pattern

- Sketch driven component pattern

- Curve driven component pattern

- Chain component pattern

- Mirror

It is used to verify interference between two or more components in a solidworks assembly.

Step-1:

Clearance Verification is used to verify the designed clearance in between two or more parts in a solidworks assembly.

Step-1: Go to Evaluate

Step-2: Select components to be excluded from study

Step-3: Define minimum acceptable clearance.

Step-4: Select the Calculate

Step-1: Ensure material or density of each part is defined.

Step-2: Click Evaluate

Step-3: Check Mass Properties.

In part/assembly: Go to Insert -> Reference Geometry -> Center of Mass

In drawing View: Go to Insert -> Model Items -> in model Item property manager under reference geometry click center of mass.

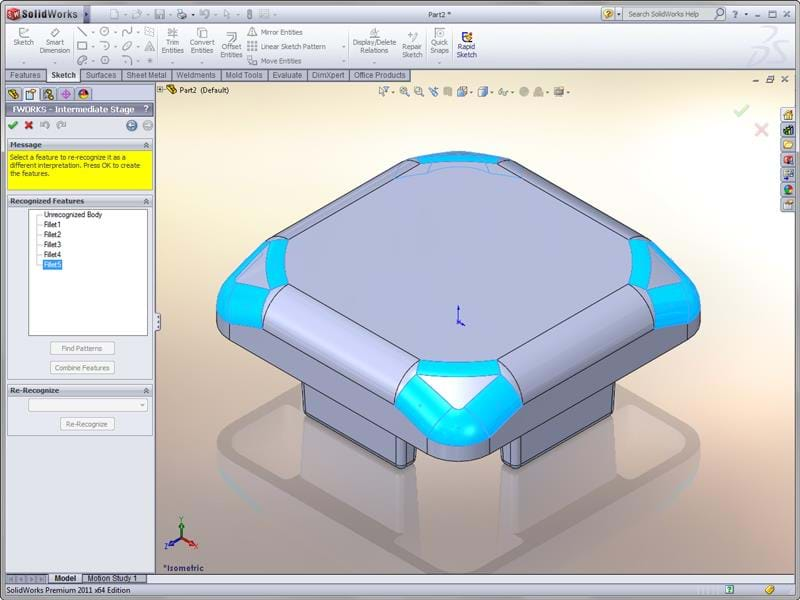

Step-1: Go to sheet Metal Module.

Step-2: Click to Convert to sheet metal

Step-3: Select Fixed face (surface from where all bends will be defined)

Step-4: Specify sheet metal parameters such thickness, internal bend radius and k factor.

Step-5: Select bending edges

Step-6: Select rip edges (SW automatically selects rip edges)

Step-7: Select corner type and corner gaps

Step-8: click ok

Step 1: Go to feature manager

Step 2: Right click on sheet-metal

Step 3: Select edit feature

Step 4: Modify sheet metal parameters

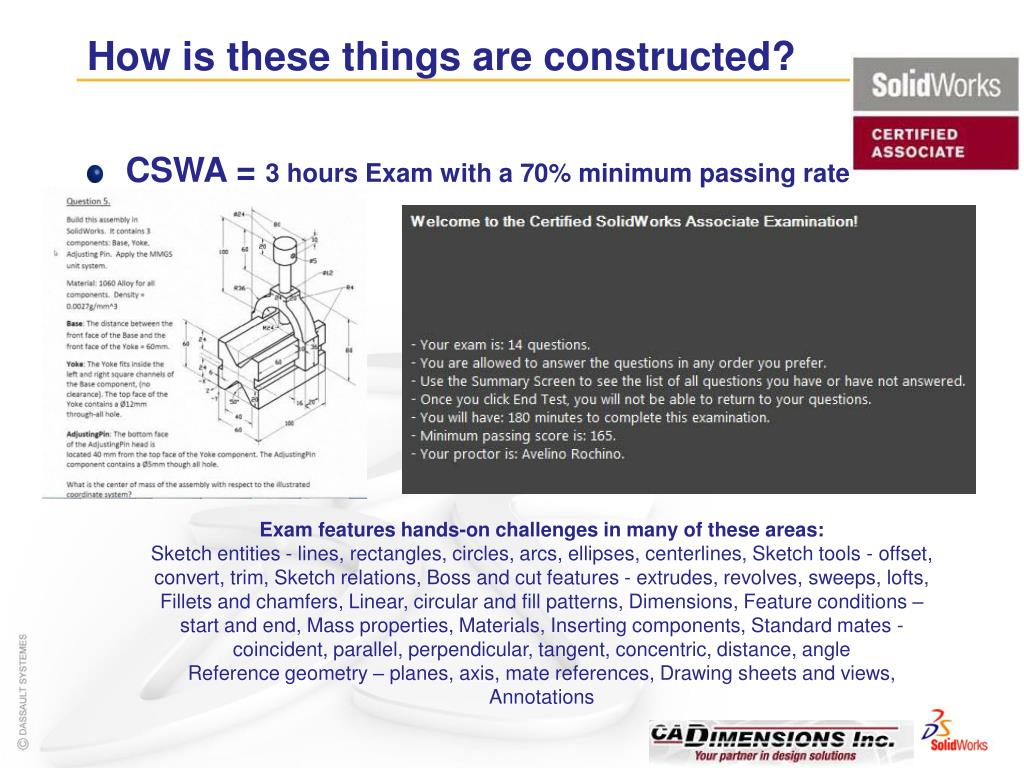

- Extrude

- Revolve

- Sweep

- Loft

- Boundary Surface

- Offset

- Fill Surface

- Extend

- Trim

- Untrim

- Knit

To make any part multi-body part merge option need to be merged.

Step-1: Go to Sketch

Step-2: Add the Text

Step-3: Extrude Cut or Extrude Base the text according to requirement.

Circuit Works is used to create 3D models of PCB data. It converts PCB data into solid works cad format.

Exploded views are used to spread out components in an assembly.

Step-1 : Go to insert and select the exploded view or go to configuration manager and right click the configuration.

Step-2 : Select New exploded view

Step-3 : Select the part to be exploded and define orientation and distance.

Step-4 : Select apply and done.

Suppressed part in solidworks is like a deleted part in an assembly while the hide is like a removed view of part in assembly.

Suppressed part in solidworks is like a deleted part in an assembly that is easy to undo. When a part is suppressed all dependencies from that part is also suppressed (features, references, mass, BOM)

External reference is used in solidworks assembly to make one part with reference to another in an assembly.

Pack & Go feature is used to copy complete assembly with all associated parts, drawings and attributes.

Step-1 :

- Standard mates: coincident, parallel, perpendicular, tangent concentric, angle, distance

- Advanced mates : Profile center, symmetry, width, path mate, linear/linear coupler

- Mechanical Mates: Cam, slot, hinge, gear, rack pinion, screw, universal joint

Step-1 : Go to configuration Manager

Step-2 : Right click part/assembly name

Step-3 : Click add configuration

Step-4 : Enter configuration name and description

Step-5 : Press ok

The Design Table is used in an assembly to control the configuration with the modification in excel sheet.

Step-1: Go to insert

Step-2 : Select Table

Convert Models To Sheet Metal Solidworks

Step-3 : Click Bill of Material

Solidworks Sheet Metal Tutorial

Speed Pack is used to create a simplified configuration of an assembly without losing references. While working with large and complex assemblies. Speed-Pack configuration can significantly improve performance.

How To Use Sheet Metal In Solidworks